Semiconductor

Flat Panel Display

Expertise of processing Slot die coater or polishing serves innovative technology for next generation.

01|Slot die coaters

Being able to process the high precise slot dies which are required coating film deviation from 2% to 5%.

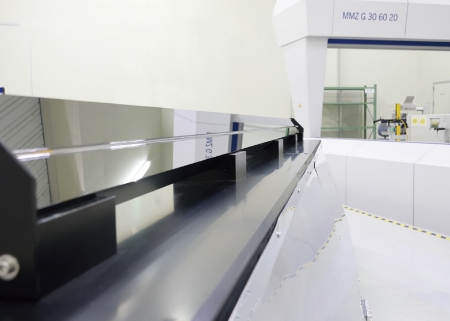

Viable to supply high precise slot dies up to 3800mm.

3800mm long Die coater

3800mm long Die coater Inspection of slot die lip with microscope

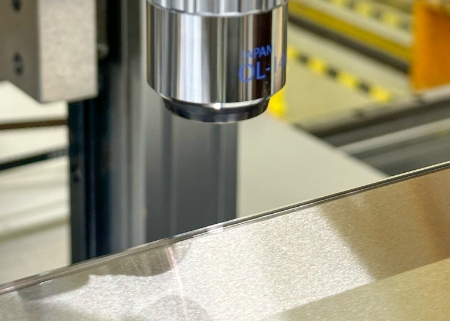

Inspection of slot die lip with microscope

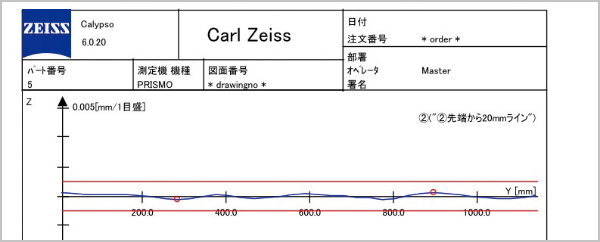

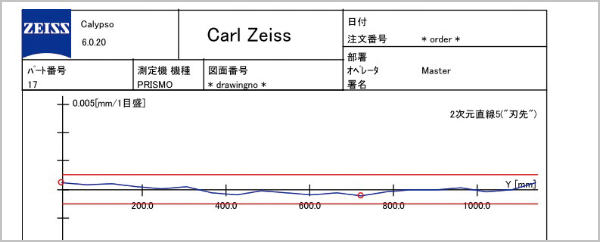

- Measuring data of slot die

Flatness of land surface 1.1um

Measuring instrument Carl Zeiss PRISMO10 - Straightness of lip surface 2.2um

Measuring instrument Carl Zeiss PRISMO10

Capability to process slot die coaters with high precision in terms of geometric and dimensional tolerances results in high-quality and low deviation coating. Viable to grind with whetstone stainless steel and cemented carbide simultaneously so that it is possible to ensure the same level of height between two materials. Also, viable to undertake repairing slot die coaters owing to grind defects off such as chipping or scratches occurred in customers’ processes.

02|Parts of semiconductor manufacturing equipment

Manufacturing and supplying indispensable high precise parts for various semiconductor manufacturing equipment.

03|Wafer vacuum table

Chuck table and slider are required to ensure high shape precision.

Viable to process convex shape and concave shape.

Wafer vacuum table

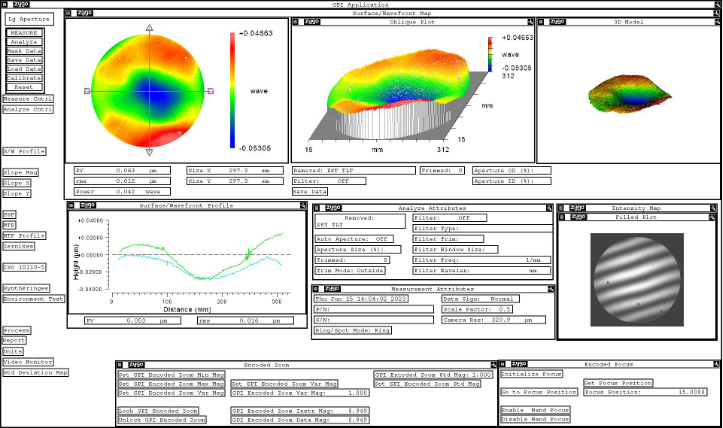

Wafer vacuum table- Measuring instrument Zygo Verifire

PV:0.063um

RMS:0.012um

New energy

New energy Optics

Optics Space / Astronomy

Space / Astronomy