NEW ENERGY

Ultra-high-precise polishing results in future new energy technologies.

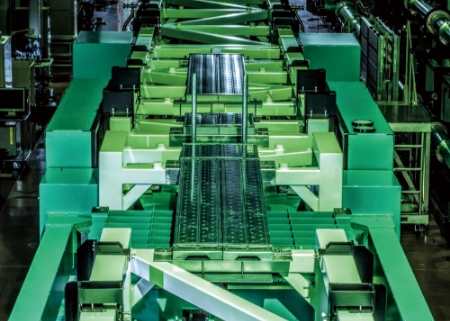

01|Slot die coaters

Slot die coaters are used in vary fields such as Lithium ion battery or films.

Having been supplying diversified models of die coaters with high precision.

Multilayer die coater

Multilayer die coater R-shape-lip die coater

R-shape-lip die coater

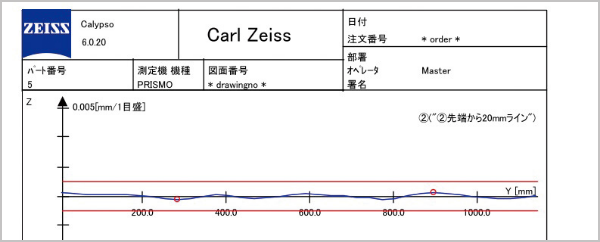

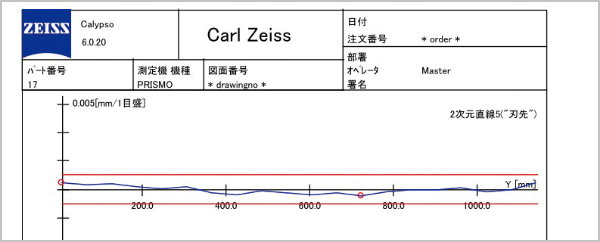

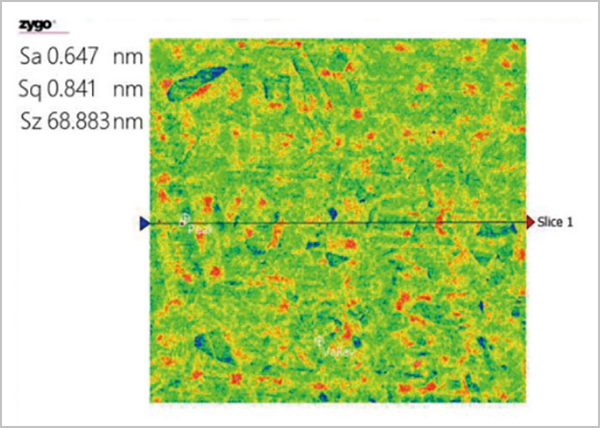

- Measuring data of slot die

Flatness of land surface 1.1um

Measuring instrument Carl Zeiss PRISMO10 - Straightness of lip surface 2.2um

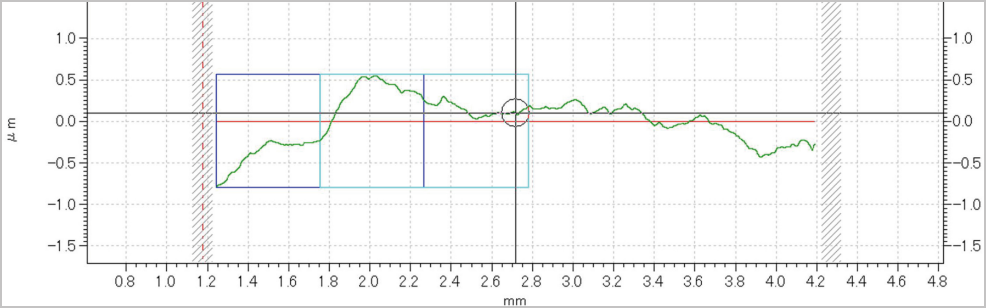

Measuring instrument Carl Zeiss PRISMO10 - Measuring data of R shape on lip

Shape accuracy PV1.3um

Measuring instrument AMETEK Talysurf

Being not only able to manufacture single layer die coater, but also multilayer one. Viable to machine and polish a variety of manifold shapes.

02|International Thermonuclear Experimental Reactor 「ITER」

Manufactured and supplied stainless mirror for R&D of Thermonuclear Experimental Reactor.

ITER:Ultra-large international project for new energy development

Material Stainless steel 316L

Material Stainless steel 316L

Manufactured toroidal-shape-mirror

400×300mm- Roughness Sa0.64nm RMS0.84nm

Measuring instrument Zygo NewView 8300

03|Institute of Laser Engineering, Osaka University GEKKO Ⅻ

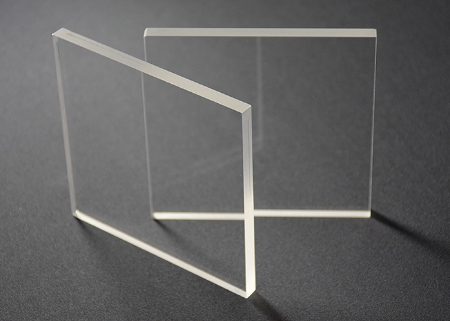

Accomplished to polish LBO single-crystal substrate for LFEX laser with significantly superb precision.

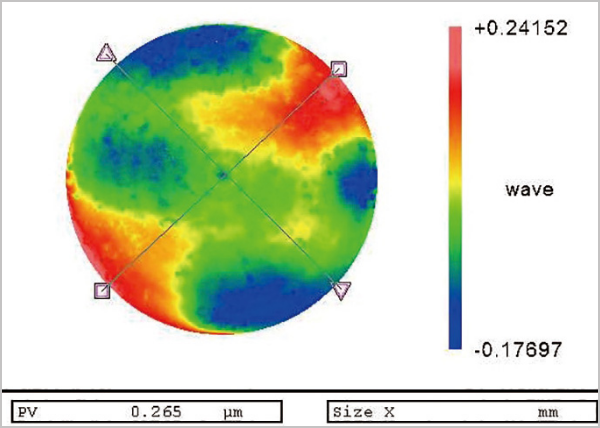

Achieved to polish the largest sized LBO single-crystal substrate in the world to install on LFEX laser in Institute of Laser Engineering, Osaka University. The disturbance of the transmitted wavefront is 0.26μm, achieving excellent polishing accuracy.

(Institute of Laser Engineering, Osaka University: Co-developed with Lecturer Yasunobu Arikawa) Image provided by: Osaka University

GEKKO Ⅻ

GEKKO Ⅻ 100x100x1.5mm Large LBO single-crystal substrate

100x100x1.5mm Large LBO single-crystal substrate- Shape accuracy PV0.26um

Measuring instrument Zygo Verifire ATZ

Semiconductor / Flat Panel Display

Semiconductor / Flat Panel Display Optics

Optics Space / Astronomy

Space / Astronomy